Sound innovations at the cutting-edge of economic technology – this has been PFISTERER’s mission statement ever since it was founded. We turn prototypes into individual solutions and individual solutions into standard products. We use our experience to improve tried-and-tested technology for practical use. And when needed, we can even break brand new ground:

- Using new materials, such as silicone, PFISTERER is pioneering new forms of insulation. It is also using new plastic-metal combinations, like the material in the ISICOMPACT tap connector. Unlike purely metallic designs, they offer considerably more freedom in design and increase the ease of installation while maintaining the same level of contact quality.

- With new technology such as shear bolts with infinite adjustment for SICON connectors, dry high-voltage terminations, or the spring-based TENSOREX tensioning system for overhead lines.

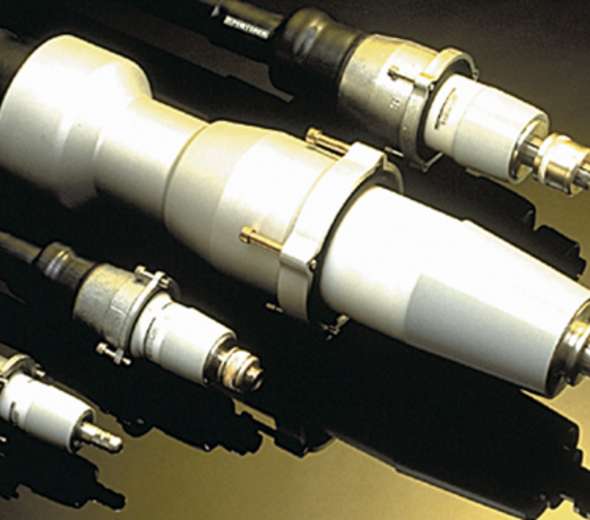

- Also with brand new solutions, such as the dry, plug-in CONNEX surge arrestors for high-voltage applications or the PLUG system for low-voltage ranges.

- And with new, ground-breaking applications in energy technology, such as the intelligent CrossPower energy management system which can be used anywhere in the world.

1968: Invention of the compact screw terminal

PFISTERER invents the compact screw terminal. From the end of the 1960s onwards, it is used to connect all new builds in Germany to underground power networks.

1969: Patent for safety strips

PFISTERER registers the patent for compact safety strips for low-voltage distributors and uses them in plastic distributing cabinets, a new development at the time.

1975: Patent for CONNEX

PFISTERER receives the patent for its CONNEX cable connection system for mid-voltage applications. This development allows mid-voltage connections to be installed as modules with factory-tested components for the very first time.

1980: Dampening elements reduce risks

PFISTERER’s mechanical dampening elements, known as AV spacers, reduce vibrations in high-voltage overhead lines caused by the wind to a safe level.

1985: SILCOSIL insulators made from silicone for the first time

SILCOSIL insulators on high-voltage overhead lines prevent voltage surges between the tower and the power line. PFISTERER’s insulators are made from silicone, a material that is much less sensitive than the porcelain and glass used previously.

2000: New fields of application for PFISTERER

PFISTERER expands its area of focus to transport technology, new energy sources, and industrial applications. The PLUG low-voltage system used to transmit high currents in harsh environmental conditions is used in railway systems for the first time. These days, almost every new high-speed train in Europe is equipped with this system.

2003: Launch of CONNEX cable connections

PFISTERER launches the CONNEX cable connections in sizes 6 and 6-S for voltage levels of 170 kV and 245 kV.

2005: Shear bolts re-defined

Easiest possible installation and optimum contact pressure for all types of conductors: PFISTERER re-designs its shear bolts for SICON screw connectors.

2007: New ISICOMPACT tap connector

ISICOMPACT is sensationally easy and more secure than ever. The new tap connector for low-voltage cables connects eight contacts with just one bolt.

2010: Off-shore approval for CONNEX

CONNEX is currently the first and only cable system to receive off-shore approval from Germanischer Lloyd.

Sophisticated solutions for specific problems

PFISTERER uses cutting-edge computer-aided simulation models in its development process in order to assess the way new buildings behave. This enables us to produce the best possible prototypes, which we then subject to rigorous development tests. Instead of focusing on a standalone product during this process, we develop complex solutions for specific problems. And we always think about the long-term effects. After all, it often takes a long time for innovations to establish themselves in the safety-conscious energy sector. The fact that we set new industry standards with our ideas and shape international conventions makes our work even more satisfying.