The main projects include the construction of one of the world's most advanced silicone processing plants in Kadaň, Czech Republic, and the relocation of the production facilities of PFISTERER subsidiary Lapp Insulators Redwitz GmbH. These measures will strengthen the competitiveness and profitability of the entire PFISTERER Group.

Cutting edge silicone processing

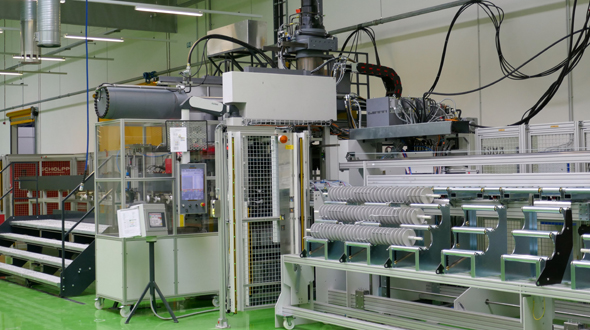

One groundbreaking measure is pooling silicone processing activities at the new site in Kadaň. While PFISTERER's proven manufacturing processes - the tried and tested materials as well as the reliable machining facilities and equipment - remain unchanged, the production environment is being raised to a new level. These include dust-free production in clean room conditions. At the Winterbach site, new products as well as special products and small series will, in the future, be tested to market readiness at a so-called innovation factory. The Group's central metals processing plant in Gussenstadt is being further upgraded to work in all relevant areas using "best-in-class" processes.

Strengthening of ceramic production

At PFISTERER's European sites in Wunsiedel, Redwitz, Turda (Romania) and Jedlina (Poland), measures to adapt the production of ceramic insulators to the drop in demand have been in effect for a long time. In-depth analyses came to the conclusion that capacities have to be permanently degraded. Therefore, the PFISTERER Executive Board decided to discontinue production at Redwitz and to relocate it to Wunsiedel, Turda and Kadaň. "This measure stabilises our ceramic manufacturing in Europe and secures the existing jobs at the receiving sites," said Michael Keinert, Chairman of the Executive Board. The relocation will be carried out during the course of 2018.