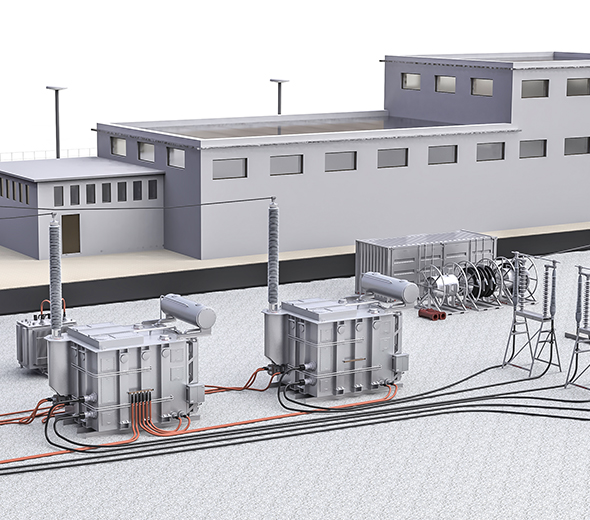

This concept is based on mobile transformers that are easy to transport, versatile in use, and quick to install. PFISTERER has developed the necessary components for this as well as extensive equipment. The first mobile units were ordered by two major utilites in the U.S.

The majority of power transformers operated in the USA were installed between 1950 and 1970 and have long since exceeded their expected service life of 40 years. If a transformer fails, it cannot be replaced quickly. It can take up to a year to build a new one, transport it to its location, and install it. In view of the daily threat of transformer failure, there is an urgent need for action among energy supply companies.

New form of mobility

One solution offering greater reliability of supply for the future is the mobile emergency transformer designed by Siemens, which is operational within a few days following a blackout. This is made possible by the pluggable, touch-proof CONNEX connection system from PFISTERER. Transformers equipped in this way can be constructed in such a compact form that they can be transported by truck or rail wagon without a special permit. For a particularly space-saving transformer design, PFISTERER developed the first dry-pluggable bushing for voltages up to 362 kV. This takes up only one third of the length that a conventional bushing requires for discharging the field control inside the transformer. Peter Müller, project manager at PFISTERER explains: "At the tip of the bushing, there is a convergence of two different field control systems. To simulate this area and design it accordingly was a great challenge, for which PFISTERER had to rely on its entire expertise as the sole supplier of pluggable HV bushings," continues Müller. Moreover, the bushings can simply be removed and transported separately if required.

Fast installation with Plug-and-Operate

A key factor in emergencies is not just simple logistics but also fast installation. For this purpose, the idea of "Plug-and-Operate" was technologically applied to the power transformers by means of the CONNEX pluggable system. A transformer equipped in this way is pre-tested at the factory, together with its bushings, so that it no longer has to be opened on site. This eliminates the need for the oil or gas work normally required in conventional systems and reduces the time required for the initial installation by up to 75 percent.

Complete from cable to glove

The engineers at PFISTERER developed an overall emergency concept that covers not only the transformer but all the necessary components and also training of the technicians on site. "Our aim was to fit everything required for the fast and smooth installation of a mobile transformer into a standard shipping container. In order to implement such a "transformer to go," we have modified or redeveloped numerous products," reports Müller. This includes, for example, specially developed uncoiling devices for the cable drums for the HV and MV connecting cables that are up to 60 m in length and weigh over a ton. They are suitable for container transport and have a drum drive that can be operated by the compressed air system of the transporter truck in the event of power failure. The cables are also equipped with fittings, tested and preassembled by PFISTERER. They are pluggable, highly flexible, and can be combined and extended by means of CONNEX connection joints. The handy lint-free cleaning cloths and gloves required for connecting the cables to the joints are also supplied, as well as pre-portioned packs of grease for lubricating the connectors.