A 66 kV cable can transmit a higher voltage with more output and yet still requires a smaller cross-section and lower current than a conventional 33 kV cable. What does this mean? Lower costs, a reduced impact on the environment, plus improved reliability and performance. To promote the technical innovations required for this, the industry and the British Department of Energy and Climate Change have initiated the OWA program with the support of Carbon Trust, an international organization committed to carbon reduction, which promotes, among other things, the development of new 66 kV inter-array cables whose connection requires advanced connection solutions.

Extensive experience in off-shore applications

CONNEX has been used in on-shore plants with a maximum operating voltage of up to 72.5 kV since 1988. This extensive experience combined with PFISTERER’s expertise in all voltage ranges mean that CONNEX was practically made for off-shore use. It has been used for inter-array cabling in mid-voltage ranges for over six years.

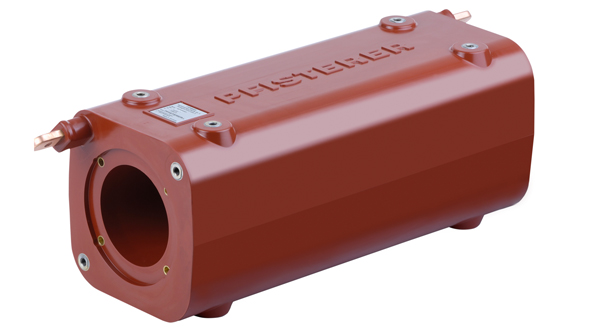

CONNEX also allows users to bring together all cable connections in a wind turbine tower: including the interior connection between the switchgears and transformers plus the connection from the external sea cable to the grid’s tower cable. In doing so, users are able to combine HV cables made from the same or different materials and connect them permanently. The interface is the new HV-CONNEX connection joint for up to 72.5 kV. It features a dry, plug-in design, and is touch-proof, resistant to salt water and UV rays, and also submersible. If water manages to enter a crack in a faulty cable, its built-in longitudinal water barrier stops the water from spreading to other connected cables. The off-shore-ready quality of CONNEX joints has been certified by the world’s largest ship and off-shore classification company, DNV GL.

Quick installation, gas free, and no maintenance

CONNEX simplifies the installation and operation of wind turbines because the plug-in system can be installed and dismantled quickly, and is completely maintenance-free. The solid-material insulation and enclosed cast resin joins do not require any SF6 gas, meaning that complex gas monitoring is no longer needed. Sheathing error testing has also got easier as it can now be performed after the joint installation without modification of the plug system – thanks to insulated contact rails for the cable shield.

The extensive portfolio for the CONNEX range includes the market’s only plug-in and touch-proof HV surge arrester up to 145 kV, along with flexible testing equipment made up of testing cables combined with the CONNEX joint. As a result, the CONNEX system has all the components you need to ensure universal connections in future 66 kV grids in off-shore wind farms.