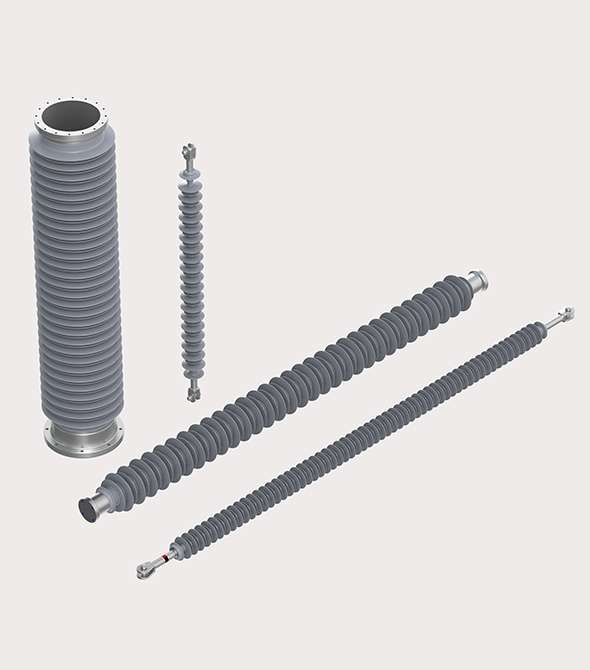

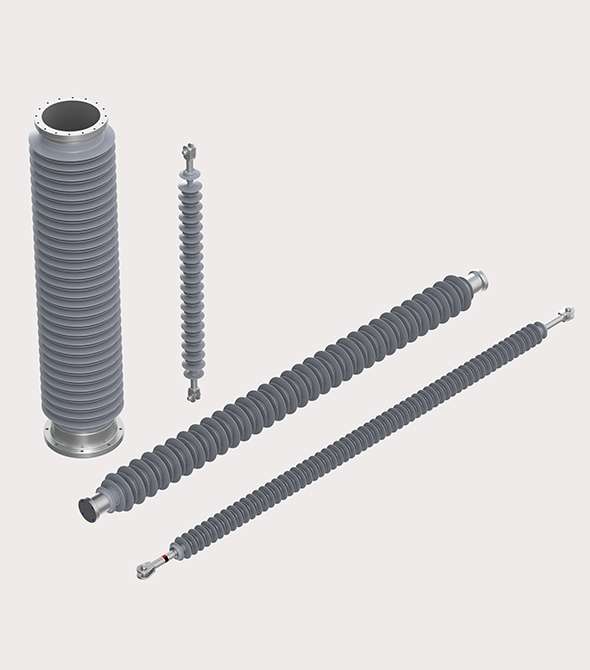

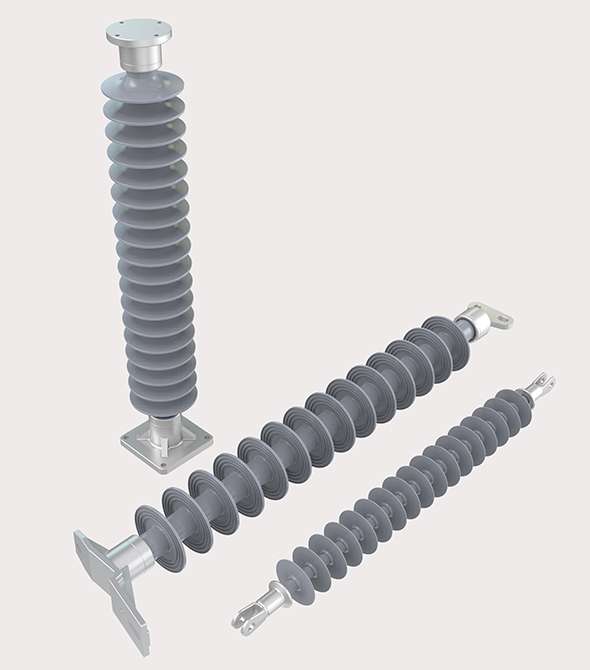

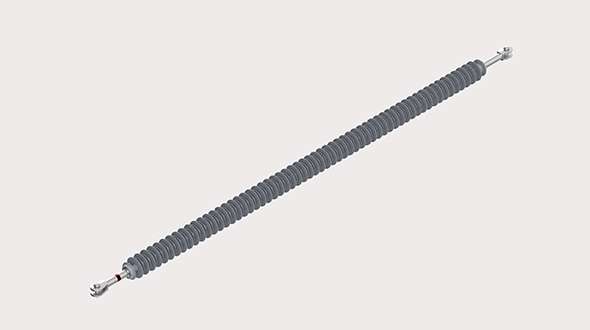

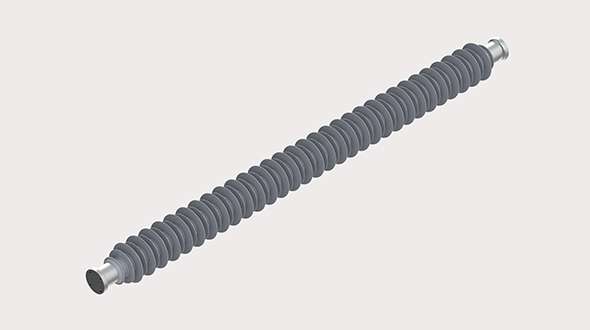

PFISTERER offers insulators for all applications in overhead line systems, substations, plant engineering, railway infrastructure and rail vehicles. The focus is on composite insulators with silicone rubber as the sheath material.

Composite insulators since 1975

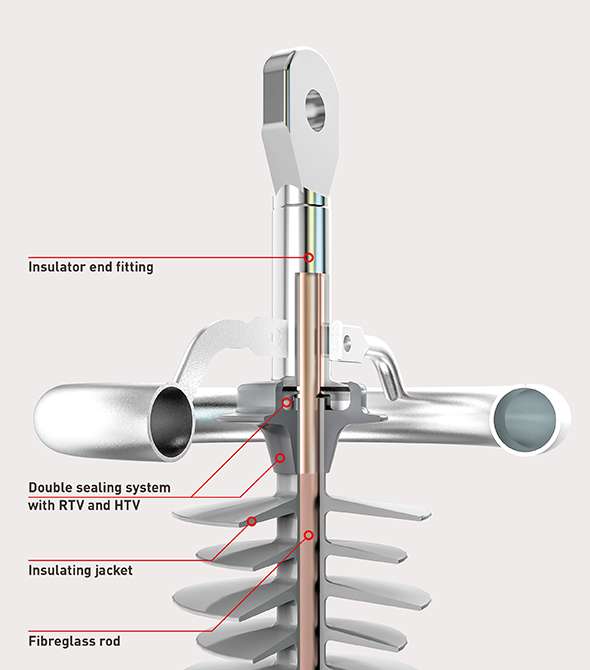

PFISTERER has been producing composite insulators for more than 40 years. Our well engineered products are able to meet all challenges, as a result of continuous optimisation based on operating experience and the knowledge gained from many years of involvement in CIGRE and IEC working groups. PFISTERER has always used exclusively silicone rubber as a shield material – mainly high temperature vulcanising (HTV) silicone rubber.