HVC8 is a plug connector for high-current applications. The robust design and high-quality materials enable reliable operation of electric motors, generators or inverters – even under extreme conditions.

Minimal space requirements

The connector system’s receptacle is integrated directly into the motor housing or device housing. A terminal box and additional seals are not required. This saves about 20% installation space and cuts costs.

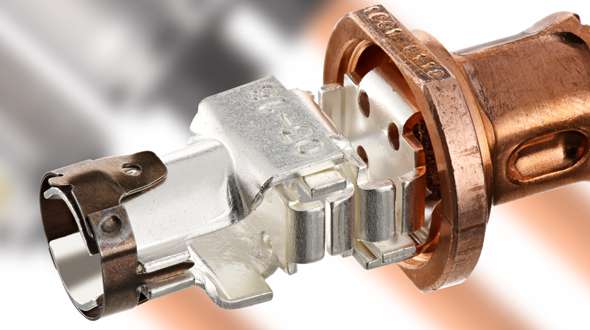

Very good EMC through shield current management

The shield current is short-circuited in the connector housing. This enables higher shield currents and therefore ensures very good electromagnetic compatibility.

Reliable operation

The receptacle is suitable for oil-insulated or cooled or air-filled drive components. Clearances and creepage distances enable operation at up to 4,000 m above sea level with an operating voltage of 900 V. Higher voltages on request.

High resistance to vibration loads

The patented contact securing method together with the patented three-zone contact system form the basis for the best possible vibration protection in operation. The solution minimises friction between the contact surfaces for noticeably improved service life and reliability. The patented three-zone contact system compensates for shocks and vibrations to ensure reliable contacting.

Long service life

The HVC8 contact technology with patented three-zone contact reduces contact resistances and maintains the contact force over the entire service life. Long-term thermally stable materials are integrated into functional elements of the contact system to ensure resistance to ageing.

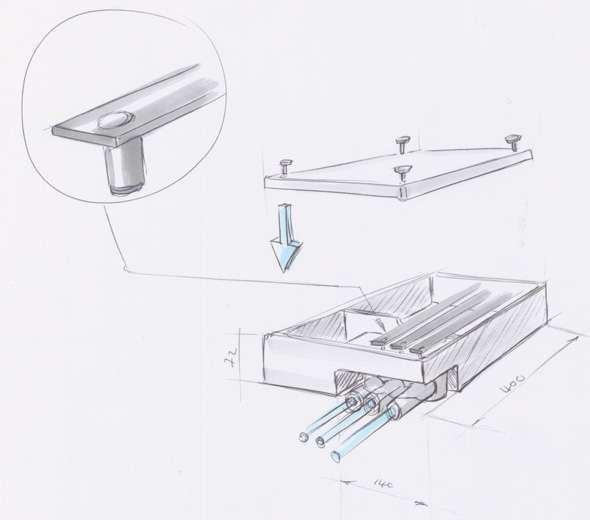

Enables industrial production

Preassembled and factory tested connector systems by PFISTERER including suitable cables reduce installation connection work to a simple plug-in process. The plug connector is secured by tightening a single screw.

Easy to integrate

Direct integration of the receptacle into the housing of power components such as a traction motor or power converter allows installation in a significantly smaller space and eliminates an additional contact point on the backside of the receptacle. Space savings of 15-20% can be achieved in this way, with lower costs and better functional reliability. The receptacle is integrated into the housing in just a few steps.