Solid-insulated and lighter than conventional oil or gas-filled terminations, dry outdoor cable terminations by PFISTERER have been used worldwide for decades. Their silicone solid insulation ensures environmental and operational safety as well as durability in use in substations and on overhead power lines, with no risk of leakage. With the new DOC (dry outdoor composite) termination, Pfisterer now also offers the first self-supporting, dry and compact version up to 170 kV. Reliable and maintenance-free in long-term use, it connects cable systems to overhead lines and busbars.

Enhanced safety with full system testing and preassembly

“The one-piece, self-supporting design reduces the number of components and facilitates installation at the place of use. The DOC central unit, comprising a hollow insulator, stress grading device and base plate, is delivered to the site fully preassembled and routine tested,” explains Tarek Fahmy, Senior Product Manager at PFISTERER. Testing under IEC 60840 section 9 is carried out on the whole central unit, instead of (as is usual) only on the stress grading device. PFISTERER is currently the sole manufacturer to offer this full testing. DOC also meets all criteria of the highest pollution class according to IEC 60815-3. It is therefore suitable for areas with high levels of dust, even deserts.

Fitted in minutes, not hours

Compared to conventional terminations, the modular design of the DOC simplifies handling across the board during transportation and installation. “The DOC offers other advantages during installation as well. That is why internally, we call it the five-minute termination,” Tarek Fahmy says. Since the central unit is fully preassembled, it simply pushes onto the cable – the number of elements to be fitted is minimised, time-consuming gluing work and drying phases are eliminated entirely. Thanks to the silicone solid insulation, no filling is required on site. The conductor is connected quickly and securely using SICON screw technology, without any hydraulic pressing tools. With FrontCon, PFISTERER offers a sophisticated connection solution even for single-wire insulated conductors.

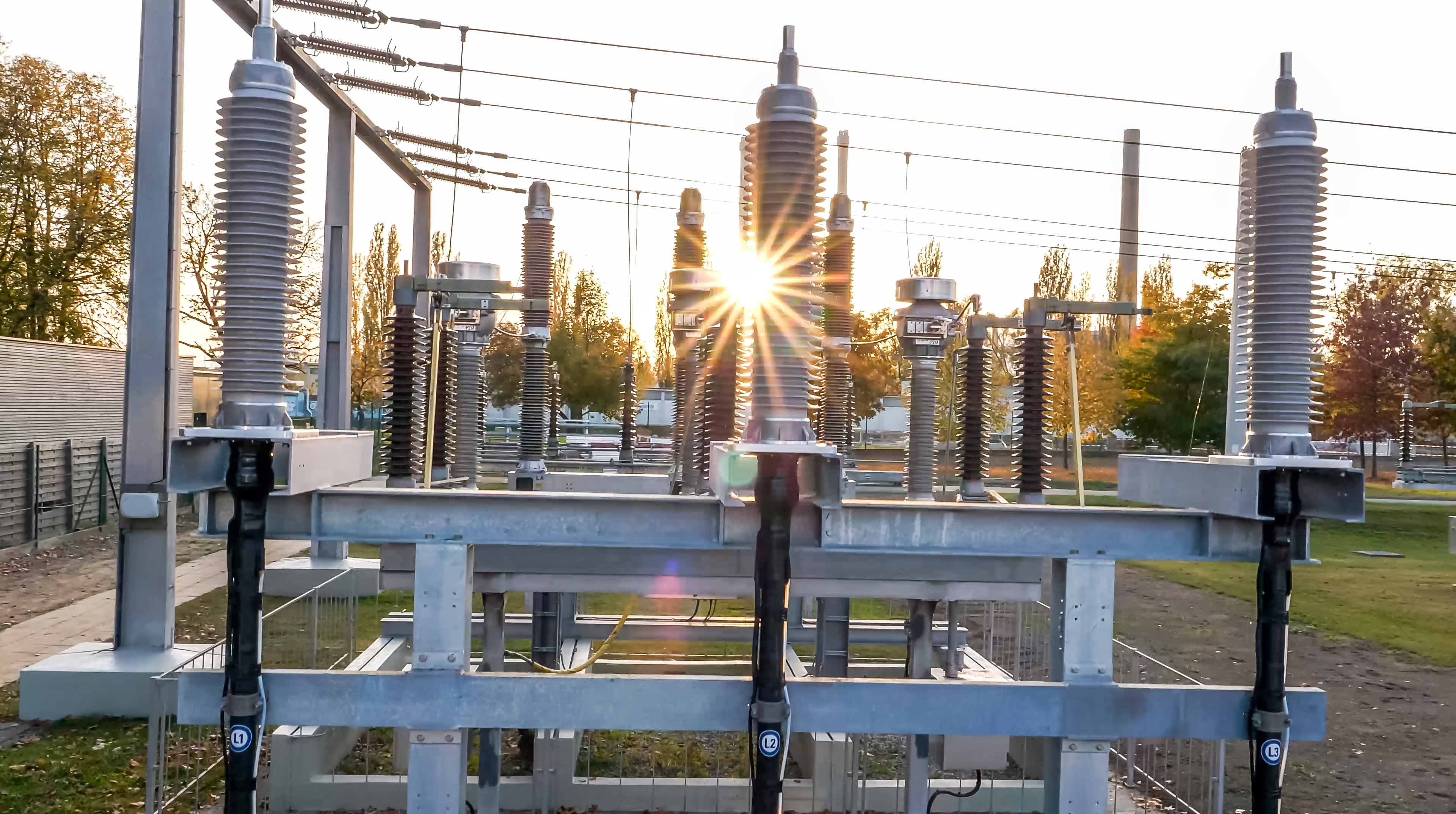

Energie Steiermark uses DOC in maintenance-free operation

Energie Steiermark was quick to recognise the benefits of the DOC termination and used the self-supporting, solid-insulated solution by PFISTERER for three newly planned terminations in a substation in Graz. The power utility and grid operator is Austria’s fourth-largest energy and services company, and is also active in Slovakia, the Czech Republic and Slovenia. The two companies have a longstanding partnership going back 70 years. The current project involves a 110 kV line with a cable cross-section of AL 1,200 mm², for which Pfisterer supplied a total of three DOC terminations including splice boxes for operational control of the cable system by means of fibre optic cable. Maintenance-free operation of the dry terminations means less monitoring is required. Another plus point is that the environmentally safe technology fulfils the company’s vision. As official partner to a green world, Energie Steiermark ensures safe, comfortable and sustainable living – so the new environmentally and operationally safe DOC is a perfect fit.