The planning and construction of complex overhead line systems requires specialist knowledge and experience, as well as the trust and cooperation of all parties involved. PFISTERER is a pioneer of innovative solutions in overhead line technology. Our products are reliably in use on all continents, sometimes under the most extreme conditions – from the intense heat of the tropics and deserts to ultra-low temperatures at northern latitudes.

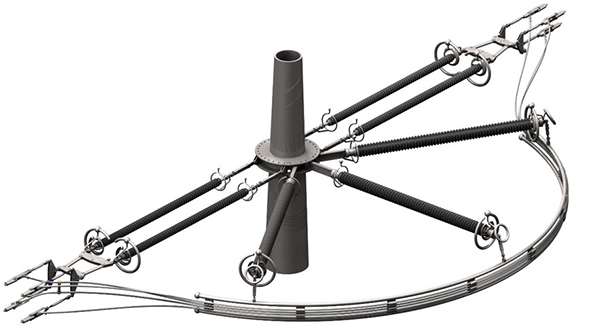

Everything between tower and conductor

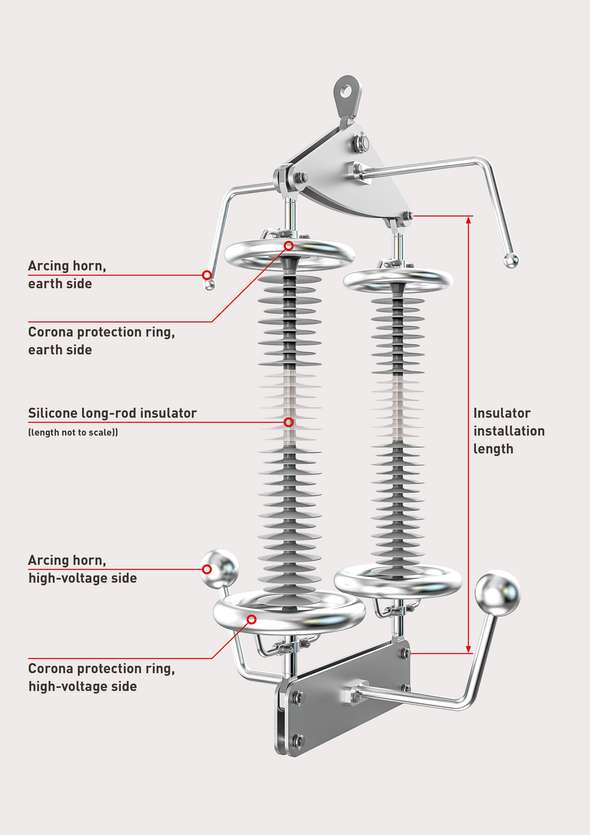

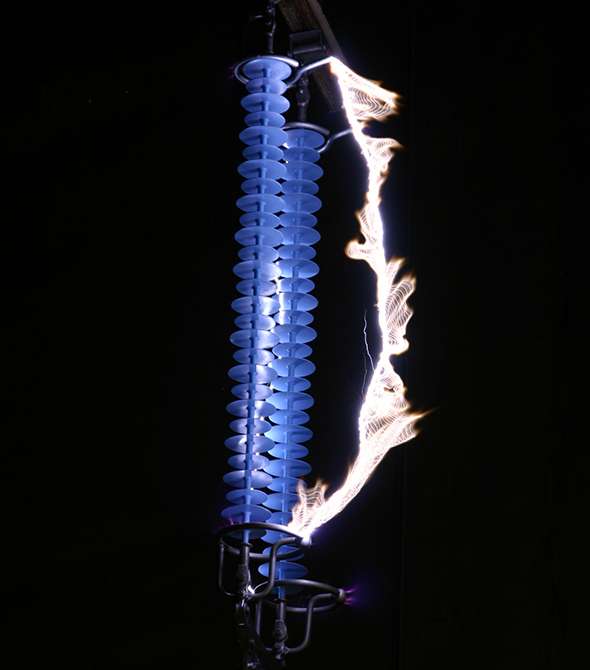

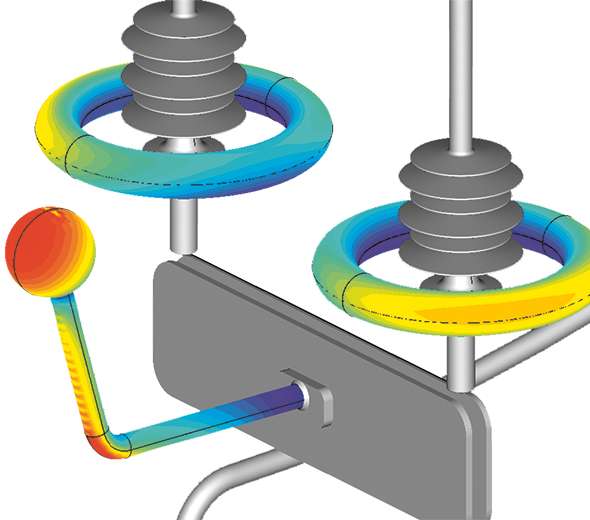

PFISTERER is a system partner with global experience in developing, designing and manufacturing complete insulator strings up to 1,100 kV. We design, produce and supply composite insulators, fittings and damping systems. Using modern simulation models for electrical field properties and mechanical loads, PFISTERER develops efficient, customer-specific solutions for complex challenges – with 100 years of experience included.